SERVICES

CNC Laser Cutting

No one in the area has more experience with laser cutting than us.

We help OEMs in all types of industries to innovate and create superior products using the best laser cutting equipment out there. Laser cutting offers higher precision and the ability to cut complex shapes.

Our Laser Cutting Capabilities

Our laser cutting machines can cut thicker materials that other laser cutters simply can't.

Up To 1" Of Carbon Steel

Up To 1” Stainless Steel

Up To 5/8” Aluminum

Up To 1/2” Brass

Up To 3/8” Copper

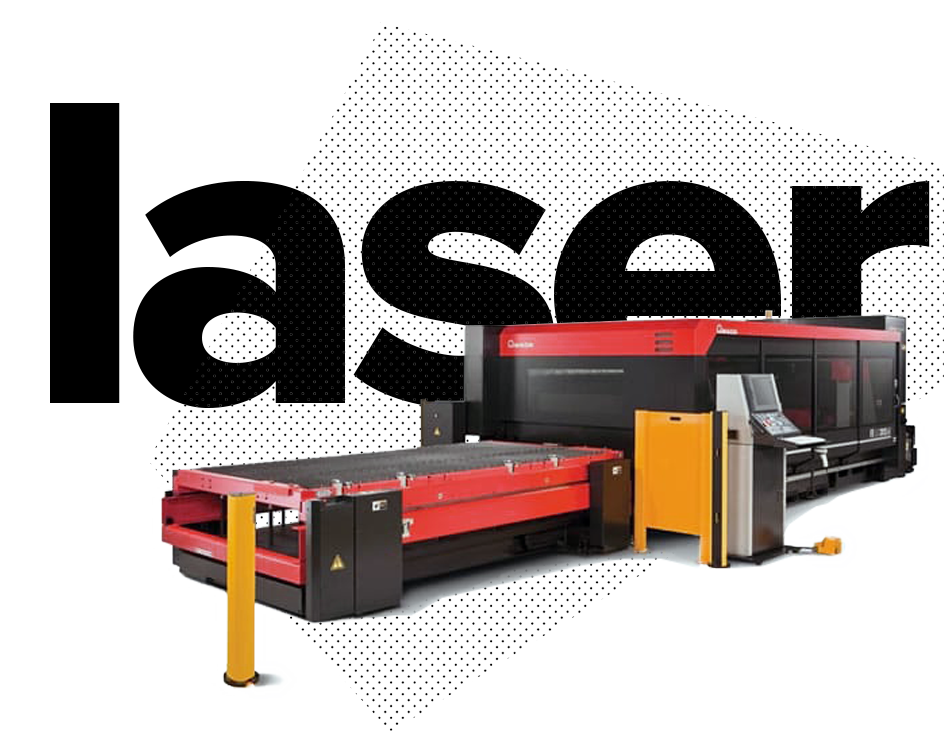

Our Laser Cutting Equipment

FIBER LASER CUTTING SYSTEM

6kW Amada LCG 3015 AJ

The Amada LCG AJ uses fiber laser technology that allows for many material types and thicknesses to be processed efficiently, including copper, brass, titanium. It features an innovative motion system and advanced structure design allow it to balance cut speeds and positioning acceleration with maximum accuracy. Amada is the world’s first manufactured fiber laser source with speeds up to 4X faster than a comparable CO2 lasers.

The Amada LCG AJ uses approximately one-third of the energy required by the same wattage CO2 laser system. It is three times more efficient with the electricity it uses, reducing costs and providing a more environmentally friendly laser system. It does not require laser gas, mirrors or other items typically associated with generating a CO2 laser beam. A single fiber optic delivery cable eliminates the need for additional external mirrors. The result is significantly lower operating costs and easy control through the AMNC 3i Control touchscreen.

LCG AJ Series Standard Features

- Includes a full enclosure that surrounds the entire cutting area with access for part removal

- Utilizes a helical rack and pinion drive system for both the X and Y axes, while the Z-axis is equipped with a high-precision ball screw

- Specifically designed to handle high-speed operation, the LCG AJ Series is also engineered to maximize safety with a sectionalized dust collection system

- AMNC 3i Control touchscreen with intuitive graphic display and with upgraded processor making it the fastest AMADA control available

- A high-speed cutting head with increased sensing speed for faster cutting and plasma resistance in thin materials

- Engineered for simplified setup, the lens and nozzle can be easily removed and installed without tools, wires or air lines

6kW Amada LCG 3015 AJ Specs and Capabilities

| Capacity | |

|---|---|

| Max. Sheet Size (X, Y) | 120” x 60” |

| Max. Axis Travel (X, Y, Z) | 121” x 61” x 3.93” |

| Travel Method | Stationary table, X, Y, and Z-axis movement for cutting head |

| Control Method | X, Y and Z (simultaneous 3-axis control) |

| Drive Motors | FANUC servo motors |

| Max. Axis Positioning Speed (X, Y) | 4,724”/min. per axis (6,693”/min. 45◦ vector) |

| Max. Z-Axis Speed | 4,724”/min. |

| Repeatability | +/-0.0002” |

| Max. Material Weight | 2,000 lbs. |

| Power Supply | 200/60/V/Hz (+/-10%), 3-Phase |

| Machine Control | |

| Model | AMNC 3i Control |

| Display | Touchscreen color LCD |

| Control Function | X, Y, Z-axis, simultaneous and focus lens B-axis, and laser power control (CW, gated pulse, pierce routines, etc.) |

| Data Storage | Compact flash drive |

| Fiber Laser Resonator | |

| Wattage | 6kW |

| CW Output Power | 6kW |

| Resonator Style | LD excited Yb fiber |

| Laser Wavelength | 1.08 µm |

CO2 CNC LASER CUTTING SYSTEM

AMADA FO 3015 M2 NT

The FOM2 NT laser represents the third generation of AMADA's proven FO series that was introduced in 1999. The FOM2 combines features available on the FO series of lasers as well as some of the leading-edge technology available on AMADA's F1 linear drive systems. Equipped with a solid-cast frame, water assisted cutting, and a high-precision motion system, the FOM2 boasts new features such as automatic nozzle changer, cut process monitoring and auto-pierce detection.

Amada FO 3015 M2 NT specs and capabilities

FOM2 3015 Features

- Maximize utilization with minimal setup between jobs

- High speed processing of thin and thick materials

- Operator-friendly windows-based network compatible control

- Performance-proven rack and pinion drive system in the X-axis and high-precision ball screws in the Y and Z axis

- High-speed shuttle table design improves overall machine utilization by externalizing the material setup process

- Cast iron frame for superior stability

- Water Assisted Cutting System (WACS™) uses an adjustable water mist to absorb heat generated by the cutting process

- Cut Process Monitoring for automatic pierce detection as well as plasma detection for thick stainless steel and aluminum

- SFP (Spatter Free Pierce) function for cleaner high-speed piercing in thicker material

- Interlocked enclosure surrounds cutting area to ensure safety

- AMADA/FANUC RF excited resonator provides unmatched performance and reliability

| Capacity | |

|---|---|

| Travel Method | X + Y - Axis Beam Move |

| X-Axis Travel | 121" |

| Y-Axis Travel | 61" |

| Z-Axis Travel | 7.87" |

| Maximum Sheet Size (One Reposition) | 61" X 198" |

| Maximum Thickness (Mild Steel) | 7/8" |

| Maximum Thickness (Stainless) | 1/2" |

| Maximum Thickness (Aluminum) | 3/8" |

| Maximum Work Weight | 2000 Lbs |

| Capacity | |

|---|---|

| Rapid Traverse X + Y | 3,150 Inches Per Minute |

| Simultaneous | 4455 Inches Per Minute |

| Z | 2, 362 Inches Per Minute |

| Repeatability | +/- 0.0002" |

| Z-axis Sensor | Hs-2007 |

| Cnc | Amnc Pc-os; Windows Embedded |

| Assist Gas Control | Automatic Select |

| Oscillator | Hs-2007 |

| Cnc | Af4000ib-4000 Watt |

| Equipped With | |

|---|---|

| Amada Fanuc Based NT CNC Control | |

| Fanuc AF4000E 4000 Watt Resonator | |

| Ez Cut System With Kaeser ASD 40ST Compressor | |

| Automatic Sheet Repositioning | |

| (1) Non-Contact Sensor Head | |

| Chiller | |

| Dust Collector | |

| Nitrogen Generator | |

| Amada LMP 3015 Sheet Load/Unload System |