SERVICES

Bending + Forming

It’s true. With extensive experience in metal bending (our forming technicians have more than 25 years’ experience), we have the skills and capabilities to handle just about any job.

Our Press Brake equipment can provide you with exactly what you need for your application: angles, “U” shapes, multiple bend shapes, “C” shapes, and more, all customized to your design. Our equipment provides both consistency for the same dimensions and fit tolerances for multiple iterations of the same part, and precision to +/- .016 (six sigma) to a feature or edge—with DSM, you can be assured you’ll get the highest quality.

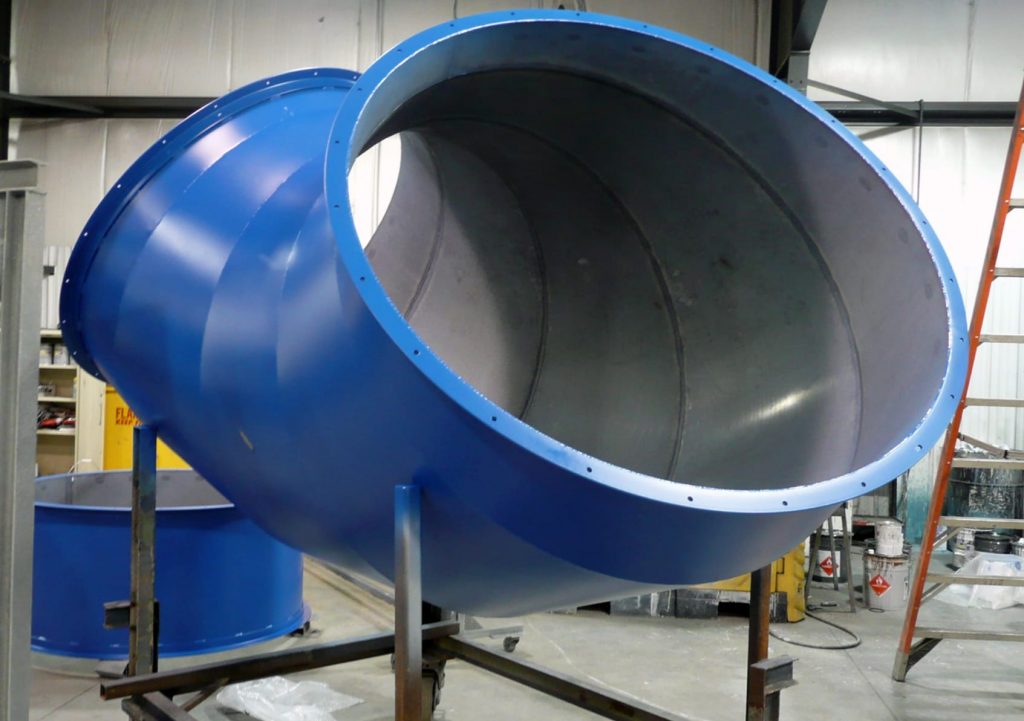

Examples Of Our Sheet Metal Bending + Forming Work

Our Metal Bending Equipment

METAL BENDING + FORMING MACHINE

AMADA FBD1253NT Press Brake

FBD1253NT, 8 axis, 125 ton, CNC hydraulic up-acting press brake with AMADA AMNC PC CNC control, 118.2” max. bending length, 5.9” stroke, simultaneous 8-axis automatic back gauge, MERLIN MTC 3000 light curtains

AMADA FBD1253NT CNC PRESS BRAKE

specs and capabilities

| Capacity | |

|---|---|

| Maximum Tonnage | 138 |

| Maximum Bending Length | 122" |

| Maximum Stroke Length | 5.91" |

| Open Height | 16.5" |

| Throat Depth | 15.7" |

| Distance Between Side Frames | 106" |

| Ram Speed: Approach | 165 IPM |

| Bending | 2.4" to 18" IPM |

| Return Speed | 212 IPM |

| Electrical Requirements | 220/460/3/60 |

| CNC Control | NT |

CNC PRESS BRAKE

Amada RG50

The Amada RG series press brakes are bending mechanisms built into a simple system. The primary concern of this original system is precision and operability. The Amada RG press brake series provides excellent performance in general sheet metal processing bending small and large parts. The numbers of Amada press brakes units installed worldwide proves its high reliability. This machine is a 55 ton RG-50 and is equipped with the popular and user friendly NC9EXII control and backgauge, which is capable of both "angle mode" and "depth mode" programming for fast set ups and versatility.

AMADA RG50 PRESS BRAKE specs and capabilities

AMADA RG50 Press Brake Features

- Designed specifically to enhance computer control

- Centralized controls provide quick, easy control of tonnage, bending depth and stroke length adjustment.

- Fully adjustable two speed operation.

- Strategic placement of the cylinders creates an ideal deflection curve, eliminating the need to shim precision tooling.

- Angular accuracy is constant over the full part length.

- Roller guiding system eliminates all ram/guide freeplay and wear.

- Tonnage limiter and gauge protect tooling and increase safety.

- Exclusive handwheel depth control simplifies set-up and reduces scrap.

- Sectionalized punch holders allow deep box forming and can create windows for long return flanges.

- Safety interlocks and overrun protectors with all step control prevents accidents.

- Smooth throttle action pedal increases operator control and safety.

- Treadle safety shield

- Exclusive tool holders simplify procedures and reduce tooling set-up time.

| Capacity | |

|---|---|

| Maximum Tonnage | 55 |

| Maximum Bending Length | 82.1” |

| Maximum Stroke Length | 3.937” |

| Open Height | 14.57” |

| Throat Depth | 15.75" |

| Distance Between Side Frames | 59.84” |

| Ram Speed: Approach | 1.8”/sec. |

| Ram Speed: Bending | 0.33”/sec. |

| Ram Speed: Return Speed | 1.38”/sec. |

| Hydraulic Pressure | 2630 PSI |